In the midst of modern manufacturing, robot arms are changing the rules of production, blending safety, precision, and efficiency in ways previously unimaginable. Robot arms are mechanical marvels which have become indispensable in all industries across the globe. They were created to reduce operating costs and keep up with the highest quality standards. Robotic arms are integrating into production lines in order to reduce cost and increase safety. Find out how these machines have transformed the industrial landscape.

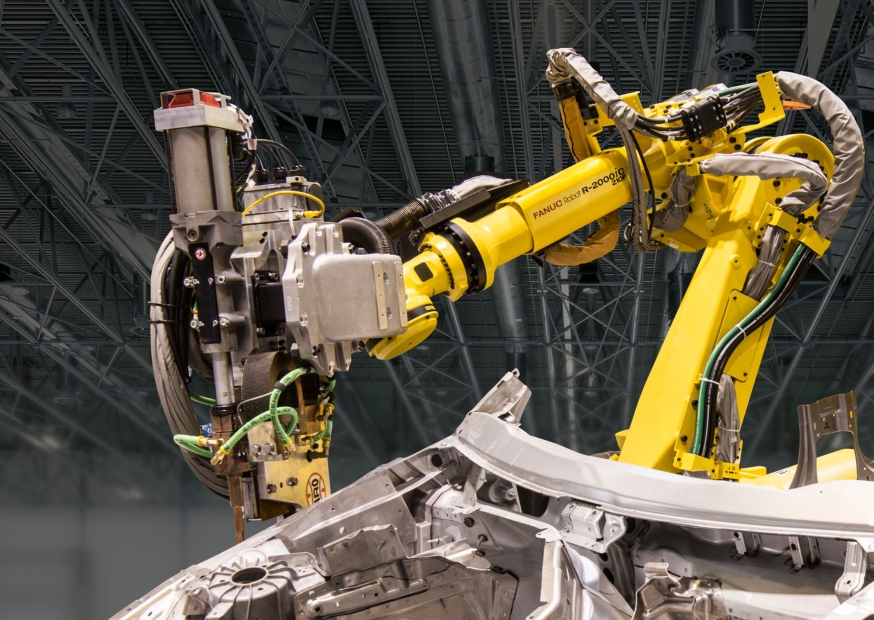

Image credit: automatedsolutions.com.au

The primary force behind the worldwide increase in robotic arm adoption is cost efficiency. Factory owners are under constant stress to prevent workplace injuries, minimize production mistakes, and minimize production waste. A robotic arm addresses these challenges head on. Robots eliminate costly errors and minimize the use of raw materials because they can perform repetitive tasks more accurately than humans. For example, in industries with high volumes such as automotive manufacturing, robot arms are able to perform precise welding and part placement to ensure perfect assembly every time. This accuracy can translate into significant savings since fewer damaged items mean less rework and less waste.

The security of robot arms is an important aspect. Human workers are at risk when performing many jobs in manufacturing, such as handling hazardous material or operating heavy machinery. By using robot arms businesses can eliminate employees from these hazardous areas, greatly decreasing the chance of injuries sustained in the workplace. A robotic arm, designed as a kinematic chain of moving joints, mimics the functionality of a human arm, however it is free of the risk of physical harm. With programmable end effectors basically robotic hands, the machines can be used for tasks like spinning, grasping, or welding in conditions that are unsafe for humans.

The versatility of robotic arms makes them a game-changer across diverse industries. Robot arms are able to be used for numerous tasks, from assembly for automobiles to electronic production. The programability of these arms lets them perform complicated operations such as painting or applying fiberglass with an unparalleled quality of consistency. In the field of warehousing, robot arms have revolutionized palletizing by automating the process of loading products onto pallets with precision and speed. The automation improves productivity as well as reliability because robot arms work constantly without fatigue.

The rise of cobots (collaborative robots) that work alongside human employees is one of the most thrilling advances in this field. Unlike traditional industrial robots confined to isolated cells. Cobots fitted with robotic arms are designed to allow safe, seamless interaction with humans. Cobots that are equipped with robotic arms are able of performing difficult or repetitive lifting tasks in a factory that allows humans to concentrate on more difficult responsibilities. Cobots will slow down or alter their movements when they see a person close by.

Robotic arms have a profound impact on modern manufacturing and not just regarding safety or efficiency. They are crucial to industries that require high precision for tasks like welding, assembly or material handling. For instance, can be utilized to rotate and position parts during assembly in the automobile industry, making sure they are aligned perfectly with no human intervention. Robot arms are also employed in electronics to care for fragile components. This helps reduce damage and improves the quality of output.

As industries continue to develop and become more complex, the importance of robotic arms is only going to increase. As they can reduce costs, improve safety, and adjust to various tasks they will become the cornerstones of the future manufacturing. Robot arms, which combine modern technology with human imagination, are not only tools they are also partners in the process. They are the engine behind technological innovation and alter how the world is built.